Why FlowKit exists

Built for small manufacturers who sell through distribution channels.

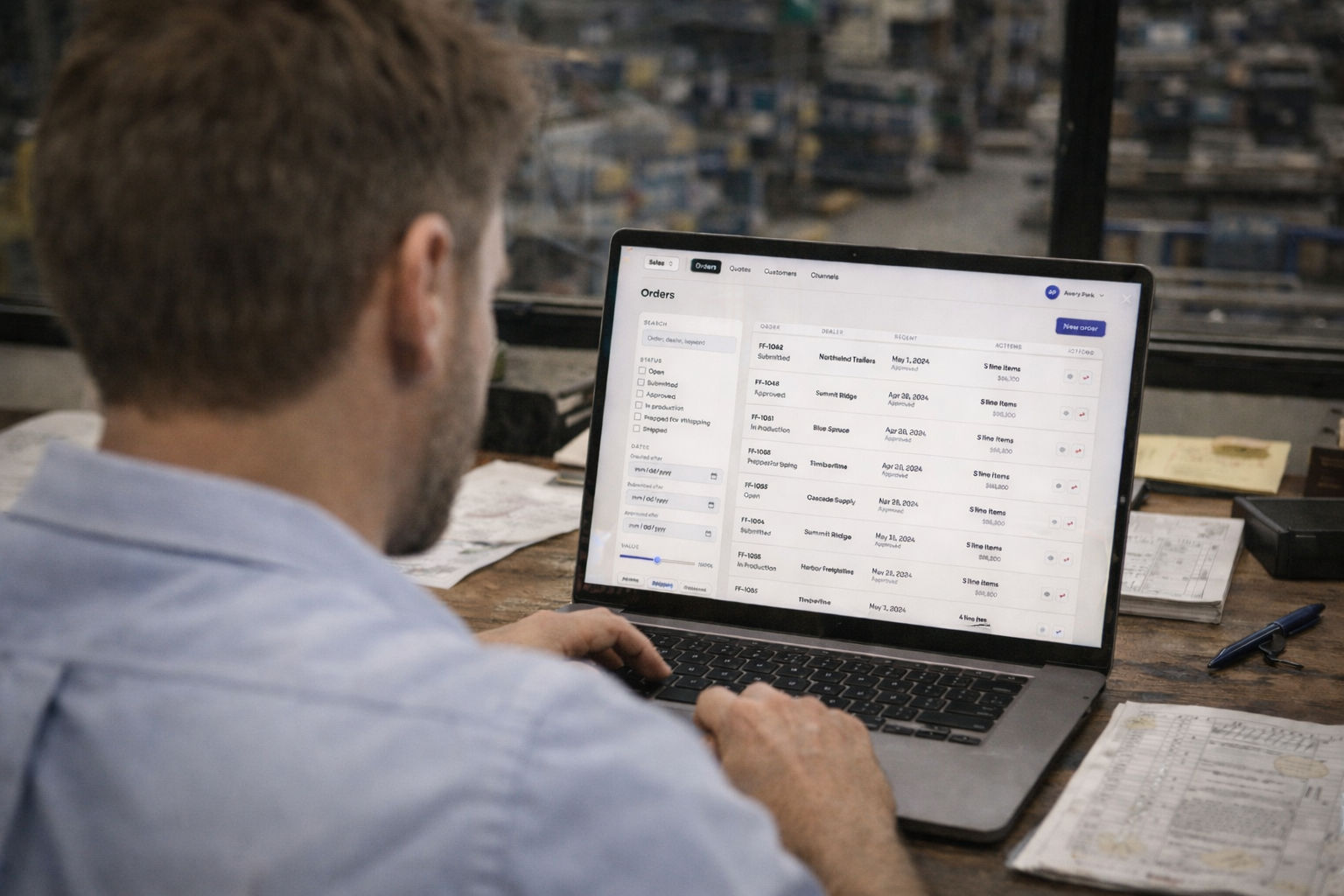

FlowKit is built for manufacturers who sell through distribution channels. It ties customer demand to production execution, inventory allocation, labor, and support so every team works from a single source of operational truth.

What FlowKit delivers

- Visibility into every unit from order to shipment.

- Structured workflows that replace tribal knowledge.

- Distributor portals that reduce status calls.

- Labor tracking tied directly to production work.

- Clean data flowing into accounting and payroll.